Passive fire protection (PFP) is integral in safeguarding assets and personnel in high-risk industrial environments. While traditional spray-applied coatings have been the industry standard for decades, technological advancements have introduced alternatives such as removable PFP and jet fire PFP systems. These modular solutions are engineered to provide reliable fire resistance while addressing operational challenges that conventional methods cannot fully resolve. Understanding the engineering principles behind these systems highlights why they are increasingly preferred in certain applications.

Material Composition and Layering Design

Unlike traditional coatings, which rely on a cured film directly adhered to the substrate, removable jet fire PFP is typically constructed from high-performance insulation materials encased in a robust, weather-resistant outer layer. The insulation core may include mineral wool, silica-based composites, or aerogel panels designed to withstand extreme heat fluxes from jet fires. The outer fabric is engineered to resist mechanical damage, UV degradation, and chemical exposure, ensuring consistent performance over extended service intervals. This layered assembly allows for precise thermal performance control and easier adaptation to various industrial structures.

Installation and Removal Mechanisms

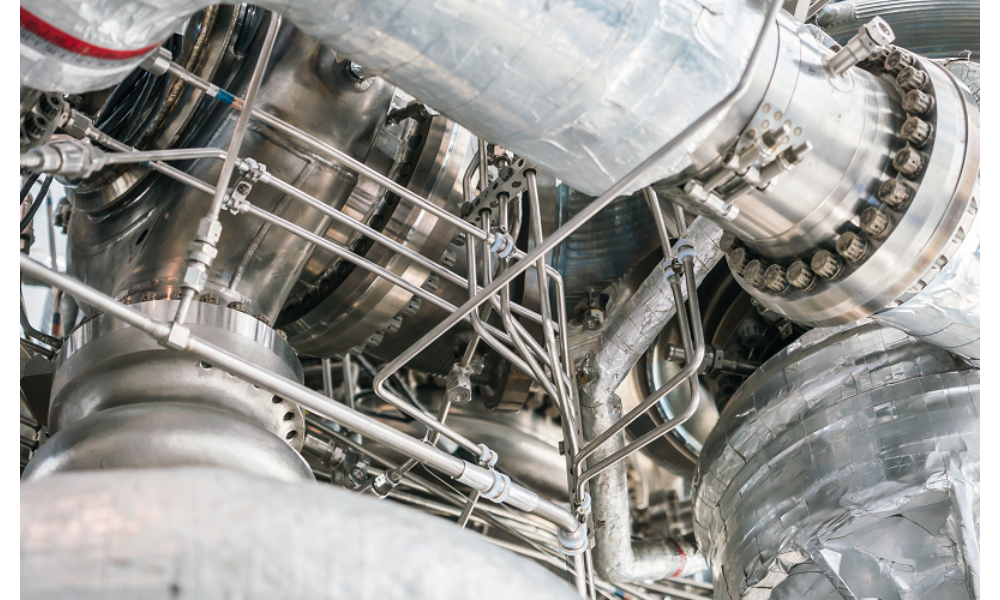

Traditional fireproofing requires onsite application, curing time, and significant surface preparation, making maintenance labour-intensive. In contrast, removable PFP is designed for quick installation and removal without damaging the underlying structure. The engineering incorporates fastening systems such as stainless steel buckles, hook-and-loop straps, or high-temperature-resistant lacing wire. These attachment methods allow for secure fitment around complex geometries like valves, flanges, and instrument panels. This approach enables routine inspections, repairs, and part replacements without the need for abrasive removal of coatings, saving both time and operational costs.

Thermal Performance in Jet Fire Conditions

Jet fires produce significantly higher heat fluxes and more aggressive flame impingement than standard pool fires, demanding specialised design features. Removable jet fire PFP systems are engineered and tested to meet international performance criteria such as ISO 22899-1. This criterion involves ensuring the insulation maintains structural integrity and prevents critical temperature rise on protected components for the specified duration. Unlike some traditional coatings that can crack or spall under rapid heating, removable solutions maintain a uniform protective barrier, aided by their multi-layered, flexible design.

Maintenance and Lifecycle Efficiency

From a lifecycle perspective, removable PFP offers significant advantages over permanent coatings. Traditional PFP may require complete reapplication when damaged or degraded, involving surface re-preparation, re-coating, and extended downtime. However, removable systems can be detached, inspected, repaired, and reinstalled with minimal disruption. This reusability extends the service life of both the protection system and the underlying asset. Additionally, the absence of on-site curing and hazardous material handling during maintenance reduces safety risks and environmental impact.

Application Versatility and Customisation

Another critical engineering advantage is adaptability. Removable jet fire PFP can be custom-fabricated to fit unique component shapes, including irregular equipment assemblies. Modular design allows replacement of only the damaged sections rather than the entire protection layer, making it a cost-effective option for facilities with frequent operational changes. Furthermore, since the protection is not permanently bonded to the substrate, there is no risk of coating adhesion failure, which is a common issue in high-vibration or high-moisture environments.

Conclusion

The engineering behind removable PFP and jet fire PFP reflects a targeted response to the operational limitations of traditional fire protection coatings. These systems deliver high-performance fire resistance while improving inspection, maintenance, and cost efficiency by combining robust thermal insulation materials, modular installation mechanisms, and reusability. Removable jet fire PFP offers a clear technical advantage over conventional coatings for industries where uptime, asset longevity, and adaptability are priorities.

Want to enhance your facility’s fire protection strategy? Visit Ancloz today and discover how we can help you achieve safety compliance, operational flexibility, and reduced maintenance downtime.